Add to Cart

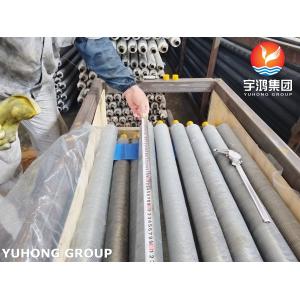

The ASTM A249 TP304 L-Type Wound Finned Tube is a high-performance heat transfer component engineered for corrosive and high-vibration environments. It consists of a welded austenitic stainless steel base tube (ASTM A249 TP304, 18–20% Cr, 8–10.5% Ni) spirally wound with Aluminum 1060 fin strips (99.6% Al) using an L-foot mechanical locking process. The "L-Type" design features fin roots extruded into precision grooves on the tube surface under high pressure, creating a seamless, gap-free bond that eliminates thermal resistance and prevents fin loosening. This hybrid structure combines TP304’s chloride resistance with Al1060’s ultra-high thermal conductivity (235 W/m·K), ensuring reliability in aggressive media.

| Component | Chemical Composition | Key Features |

| ASTM A249 TP304 Base Tube | • Cr: 18–20%, Ni: 8–10.5%, C: ≤0.08%, Mn: ≤2.0%, Fe: Balance. | • Excellent pitting/crevice corrosion resistance. |

| Aluminum 1060 Fins | • Al: 99.6% min, Fe+Si: ≤0.40%, Cu: ≤0.05%. | • Superior thermal conductivity (235 W/m·K). |

| Synergy | • Anodized fin roots prevent galvanic corrosion at steel-aluminum interfaces. | • Stable in pH 3–12 environments. |

| Component | Mechanical Performance | Key Features |

| ASTM A249 TP304 Base Tube | • Tensile Strength: 515–860 MPa | • Pressure rating: 25 MPa at 150°C. |

| Aluminum 1060 Fins | • Tensile Strength: 70–110 MPa | • Lightweight (2.71 g/cm³) for 30% weight reduction. |

| Bond Performance | • Shear Strength: ≥40 MPa. | • Thermal cycling stable (ΔT 300°C, 5,000 cycles). |

·Chemical Processing: Sulfuric acid coolers, chlorine condensers, and solvent reactors.

·Food & Beverage: CIP-compliant pasteurizers and fermentation tanks (FDA/3-A certified).

·Power Plants: Flue gas heat recovery boilers and economizers.

·Marine Systems: Seawater-cooled condensers and desalination units.

·HVAC/R: Industrial chillers and heat pumps for humid environments.

4. Why Choose This L-Type Finned Tube?

·15% Higher Heat Transfer vs. standard spiral fin tubes.

·Zero Fin Lift-Off: L-foot locking ensures permanent bonding.

·40% Lighter than solid fin designs, reducing structural costs.

·Certified Quality: ASTM A249, ASME SA-249, ISO 9001, and PED 2014/68/EU.

·20-Year Service Life in saltwater/acid vapor environments.